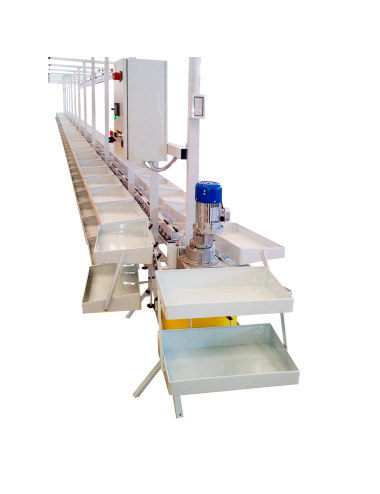

The machine consists of a sturdy metal structure equipped with feet that supports all the organs necessary for operation.

The structure is made up of a variable number of modules that allow the construction of different lengths.

At one end (driving head) there are the engine and the driving ring gear, while at the other end (driven head) there is the idling ring gear.

The chain, driven by the drive crown, moves the trolleys by means of suitable hooks.

In the upper part there are vertical T-shaped structures, for fixing systems serving the machines placed around the conveyor such as overhead channels, while the support on the ground takes place by means of a series of feet.

The electrical and control panel is fixed on the first of these T-supports, on the side of the drive head.

All the machines and equipment necessary for the workers to process the products placed on the trolleys are arranged around the conveyor.