- Company

-

Footwear Machines

- Production Lines for Shoes Factories

- Work Tables

- 3D Printers

- Laminators

- Fusing Machines

- Halogenation Machines for Shoe Soles

- Machines for Setting Studs

- Machines applying hooks

- Edge Taping Machines

- Insoles Performing Presses

- Vis Applying Machines

- Forniture

- Heel Seat Lasting Machines

- Thread Burner Machine

- Punching Machines

- Crimping Machines

- Roughing Machines

- Compressors

- Dryers

- Finishing

- Uppers Fixing Machines

- Dryer and Glue Re-activators

- Cooler Tunnels

- Die-cutting Machines

- Toe Lasting Machines

- Backpart Moulding Machines

- Powder Actuated Nailers

- Cementing Machines

- Nail Puller Machines

- Form-Levering Machine

- Hot Glazing Machines

- Machines for Applications

- Sides lasting Machines

- Eyeleting Machines

- Pulling-over and Lasting Machines

- Industrial Presses

- Reactivators

- Hammering Machines

- Trimming Machines

- Riveting Machines

- Folding Machines

- Shaping Machines

- Grinders

- Skiving Machines

- Stands

- Splitting Machines

- Brushing Machines

- Planing Machines

- Ironers

- Cutting Machines

- Traysealers

- Thermo Ironers

- Edge Dyeing

- Stamping Machines

- Universal Printing Frames

- Steaming Machines

- Sewing Machines

- Marking Machines

- B-TUBE

- Spare Parts

- Guaranteed Used

- Brands

- Support

- Contacts

Home

Omac

990TE-V MINI

Edge dyeing machines equipped with painter rollers of different diameters, suitable to be used in the sectors of leather goods, footwear, watch making, furnishing, nautical, automotive and leather items:

- Equipment: 2 rollers (a "L" and with grooves)

- Motor with variable speed control

- Edge Dyeing Machine with extractable head

- Horizontal Edge Dyeing with painter roller of 16 mm diameter

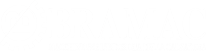

Stema

ER26TR

Dryer and glue reactivator

- This machine is a linear shoe and sole transporter which reduces solvent evaporation times

- CHARGING: The operator or operators gluing by hand or by machine place the sole and shoe on the conveyor belt

- EVAPORATION: Inside the tunnel the solvent contained in the glue is forced to evaporate.

- REACTIVATION: The press operator takes shoe and sole at the end of the cycle perfecly reactivated and ready for assembly. The reactivation temperature is guaranteed by tow optical sensors. You can be included, for the form, the OPANKA reactivation.

Transmatic

REV 5S

Elecrtric heat swinger press with double plate and lateral move.

- Long lasting strong construction and a good pressure

- No compressed air needed

- Half-automatic closing and automatic opening

- Electronic and digital touch screen with visual control of temperature, pressure and time with advice of eventual errors

- Exchangeable under plate

- Closing using the side buttons / Automatic opening

Omac

997 TR 2

Automatic horizontal belt edge inking machine with variable speed for small, shaped parts, possibility to ink parts from a minimum of 2.5 mm o width and 50 mm in lenght.

The 997 is a newly redesigned belt dyeing machine with a revolutionary working system.

Featuring a horizontally positioned working table, this machine allows considerable physical energy saving with a significant increase in productivity.

- It is suitable to dye belts and folded edges for luggage and leather goods in general (width from 10 mm to 60 mm) and also allows pre-dyeing fo the belt tip

- It is fitted with photocell that allows to proceed material rapidly

- The machine can be supplied whit or without stand

Intercom

I788

Banco aspirante B7 dispositivo d'incollaggio S8 e contenitore CO composto da:

- Banco aspirante con ottima capacità di contenimento delle nebulizzazione, corredato con un motore silenzioso e potente

- Pistola G6 studiata sia per incollaggi di precisione che larghe superfici. Nello specifico è possibile effettuare spruzzature da un minimo di 3 mm ad un massimo di 50 mm

- Contenitore inox da 5 lt. rivestito con teflon antiadesivo

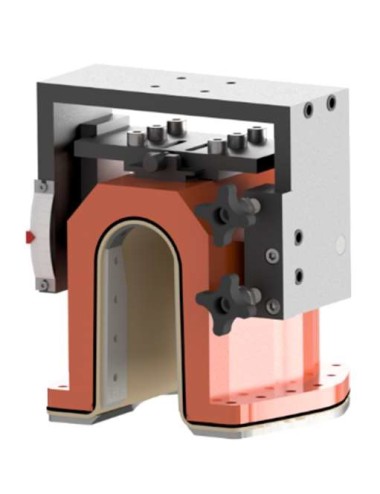

Oshima

OP-450GS

The most popular, universal continuous fusing machine.

- The belts width 45 cm

- One side open machine makes possible fusing the fabric width larger than the width of belt.

- It is also possible to fuse on the edges without the necessity of thermal processing whole the surface of fabric.

- Maximum dressing width 44 cm

- Maximum pressure 1,5 Kg/cm^2

- Electronic temperature control assure even and durable join of the fabric with fliselin or interlining

- Rotary scrapers prevent the interlining clinging to the belts