I388

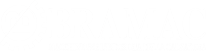

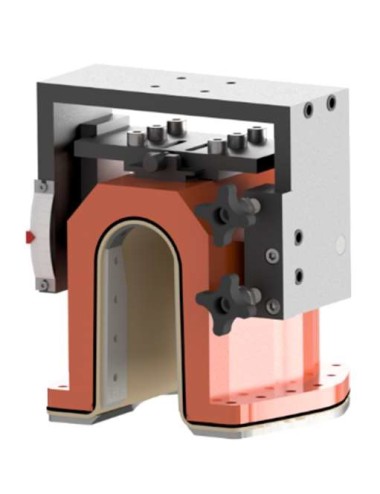

Macchina composta dal banco aspirante B3, dispositivo d'incollaggio S8 e un contenitore CO montato e installato.

- Banco aspirante creato per essere appoggiato sul banco di lavoro ed equipaggiato con un silenzioso e potente motore per offrire una maggiore capacità di contenimento della nebulizzazione.

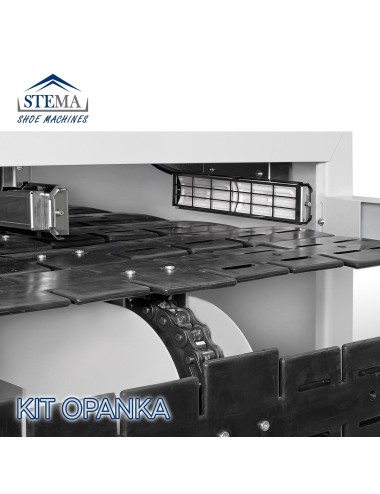

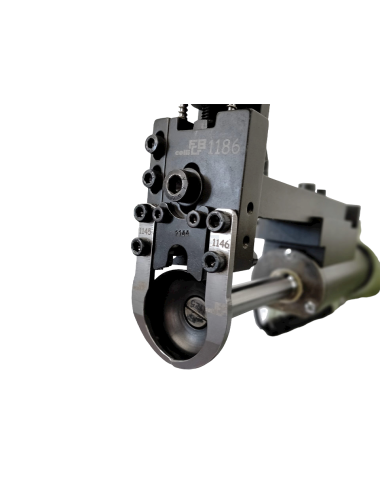

- Pistola G6 studiata sia per incollaggi di precisione che larghe superfici. Nello specifico è possibile effettuare spruzzature da un minimo di 3 mm ad un massimo di 50 mm

- Contenitore inox rivestito con teflon dalla capacità di 10lt