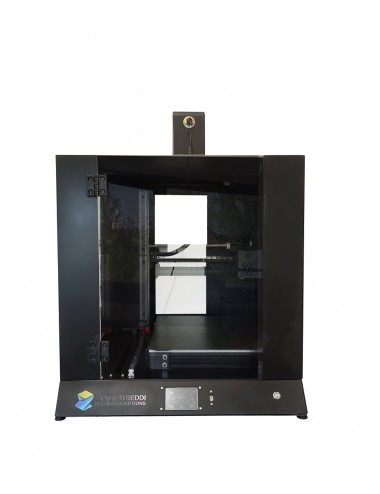

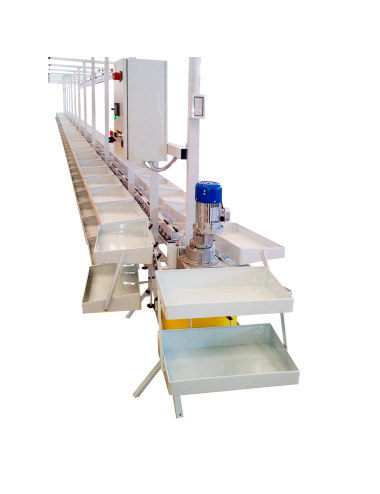

Bramac BR-850

Automatic edge folding machine ideal for different types of processing

- Equipped with different working modes, automatic and manual

- It can fold both sides, only above and only below

- The molds are quickly and easily equipped

- The upper mold is heated with the possibility of regulating its temperature