APPLICATION AREA

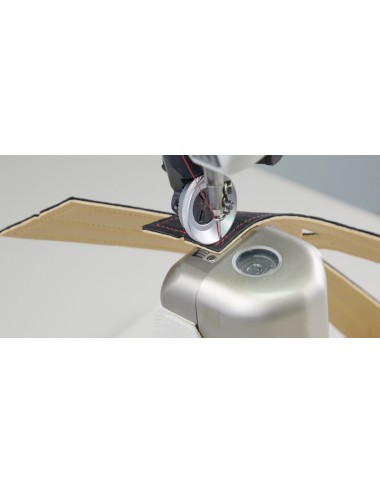

Its particular needle tip transport system allows the sewing of difficult materials such as upholstery, or of multi-layered materials avoiding sliding. In the processing of closed uppers, the right column allows you to freely guide the upper on the left side of the column, very useful for children's uppers.

Equipped with thread trimmer, electric backtack automatically activated by lever or push-button panel and the lifting of the electric foot.

Continuous operation of the rotating feed dog and the roller foot synchronized considerably facilitate the guiding of the material making the work more efficient and qualitatively better.

The machines of this series can be had with a narrow low column and with a special high column with an electronic needle, with integrated servo motor, THREAD TRIMMER / BACKTRAKING, double transport with synchronized rotors by means of stepper motors.

Horizontal axis crochet for driver-type seams and models with angled seams on the heel. It is also characterized by being "well" allowing for a versatile use like a normal column machine.

The new innovative and ergonomic design, combined with a touch screen control panel, a more usable sewing area and a new LED lighting, ensure that the operator has more space available with a high level of comfort visual and working.

It designs entirely from scratch, both in design and in internal components to offer a highly innovative product, it is characterized by an intuitive and versatile software that allows programming and automation of numerous functions and processes offering qualitatively homogeneous and well made seams.